Quartz slabs are robust, corrosion-resistant, heat-resistant, wear-resistant, scratch-resistant. They are really popular among consumers and have progressively taken front stage in the home design market as they are so extensively employed.

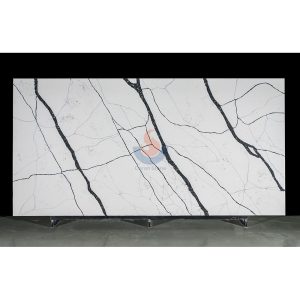

Calacatta Quartz 20mm

Artificial quartz slab standards

Regarding artificial quartz slabs, China’s standard “Artificial quartz slabs for building materials decoration” (JG/T463-2014) defines it as a decorative slab made of quartz crystals or silica sand as the main filler, adding other functional materials, and mixing, molding, and curing with adhesive materials.

Artificial quartz has a dense structure, hard texture, no radiation, zero formaldehyde, moderate hardness, and low processing difficulty when compared to other artificial stone slabs including natural stone. It is extensively applied in industries including kitchens, toilets, public restaurants, and interior design and décor.

Artificial quartz manufacture technology in China has advanced quickly. Relatively developed artificial quartz manufacturing clusters have emerged in Guangdong, Hubei, Shandong, and other Chinese areas. Leading enterprises in the sector have shown great worldwide competitiveness in the domains of automated production, product performance research and development, and pattern design. The fake quartz business still has great market potential in China as China’s house construction materials market keeps improving; its raw material plate sand market will also be active and consumer demand will show positive increase.

Special quartz sand for artificial quartz stone plates

Usually formed of 95%–99% quartz sand or quartz powder glued and cemented by resin, colorant, and other ingredients, artificial quartz stone plates Artificial quartz stone plates’ performance to some degree depends on the quality of quartz sand or powder.

Made from quartz ore taken from mines via crushing, screening, washing, and other operations, quartz sand and powder Products with a fineness less than 120MESH are generally known as quartz sand; products with a fineness more than 120MESH are known as quartz powder.

High temperature resistance, modest thermal expansion coefficient, great insulation, corrosion resistance, piezoelectric action, resonance effect, and special optical qualities define quartz sand.

Mostly found in Guangdong, Guangxi, Hainan, Fujian, Yunnan, Sichuan, Hubei, Heilongjiang, and other areas, China boasts rather abundant quartz mineral deposits comprising quartzite, quartz sandstone, natural quartz sand, vein quartz, etc. Usually, areas of quartz mining guide the establishment of quartz sand processing plants. Although China boasts several quartz sand processing facilities, most of them are small in scale and have low output capacity. The texture of the ore veins they depend on determines most the grade of the quartz sand generated.

Processing process of quartz sand for plates

Quartz ore extracted from mines is crushed, screened, water washed, and other techniques produces quartz sand. Quartz sand processing for plates: big stones enter the warehouse-high-pressure water washing.- coarse crushing-fine crushing-sand making machine vibration screeningSand washing machines eliminate completed sand-drying machines or natural drying.

The techniques followed for the sand washing process vary depending on the quality of the quartz ore. Usually, regular water washing is enough if the ore quality is pure and contamination is low. If it contains more mineral impurities, it needs to be acid-leached first, and then the subsequent process is carried out.

Acid leaching is a chemical process for purifying quartz sand. It makes use of the fact that, save from HF acid, quartz is insoluble in acid; other impurity minerals can react with acid to produce soluble salts, hence purifying quartz.

Single acid leaching, mixed acid leaching and complexation constitute the several forms of acid leaching. Sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid and hydrofluoric acid are among the often used acids in acid leching. Complexation is a technique that reduces the amount of impurity ions in the quartz sand by means of the fact that the impurity ions in the sand can form complexes with high solubility with the anions in the acid solution following treatment of the sand with acid leaching. Mostly oxalic acid and acetic acid, the often utilized acids in the complexation are Under appropriate conditions, these acids can effectively remove metal impurities in quartz sand. For instance, dilute acid can efficiently eliminate iron and aluminum contaminants; but, for removal of chromium and titanium, a larger concentration of aqua regia, sulfuric acid, or hydrofluoric acid is necessary. Quartz sand particle size, acid solution concentration, acid leaching temperature, acid leaching time and solid-liquid ratio define the primary elements influencing the effect of acid leaching.

In addition, if the quartz sand is required to have a high purity, deionized water or distilled water should be used to clean the acid solution during the acid leaching process to prevent the metal impurity ions dissolved in the cleaning water from causing new pollution to the quartz sand. Usually by evaporation and condensation, the acid used in the acid leaching process to purify quartz sand can be regenerated or even recycled several times, therefore reducing the negative environmental effects.

Green Excellent Quality Hotel Wall Countertops Artificial Quartz Slabs Engineered Stone With Veins

An significant industrial mineral raw resource, quartz sand finds use in glass, casting, ceramics, refractory materials, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemical industry, plastics, rubber, abrasives and other sectors. Nowadays, people’s life is much enhanced by plate sand, which is also really handy. But with the hot quartz sand market, premium quartz sand resources are becoming less and less available, and quartz stone plate businesses are running across raw material shortages. One of the main drivers of competitiveness for plate firms now is having premium raw material supplies.