In today’s pursuit of high-quality architectural decoration, marble mosaic has become the preferred material for designers and architects with its unique beauty and durability. However, to fully realize its potential, advanced construction methods must be adopted. This article explores and proposes improvement measures to improve the construction process and ensure the beauty and durability of marble mosaics.

Marble mosaic bathroom effect diagram

1. Innovation of paving technology

The paving process directly affects the beauty and stability of marble mosaics. To improve the paving process, high-performance glue-containing slurry must first be used to enhance the adhesion between the bottom slurry and the back mesh. The perforation technology of the back mesh allows the bottom slurry to penetrate into the gaps between particles to form a strong bond. In addition, the use of interface agents further improves the bonding strength and ensures the long-term stability of marble mosaics.

2. Strategy of overall grouting reinforcement

Overall grouting reinforcement is a key step to ensure that mosaic particles and the bottom slurry form a solid whole. Liquid glue is widely used due to its excellent permeability and bonding strength. During construction, the dilution, curing time and shrinkage of the grouting material must be carefully controlled to achieve the best grouting effect. The application of multiple grouting methods ensures the full filling of gaps and the overall reinforcement of marble mosaics.

3. Fine operation of flatness grinding and polishing

In view of the different thickness of marble mosaics and the unevenness after paving, flatness grinding has become an important part of improving the quality of the finish. Select suitable grinding equipment and abrasives, strictly control the grinding amount, and finely grind the edges and corners to achieve the ultimate flatness and gloss of the marble mosaic surface. This process requires meticulousness to ensure that every detail meets the perfect standard.

Natural Oriental White Marble Long Octagon Flower Mosaic Tiles

4. Comprehensive optimization of construction methods

Deepening of paving technology: During the paving process, the seamless bonding of marble mosaics and the base layer is achieved by precisely controlling the amount of base slurry and the coating of interface agent.

Fine regulation of grouting reinforcement: Use multiple grouting, carefully observe the penetration and curing process of the grouting material, and ensure the complete filling of the marble mosaic gaps.

Process improvement of grinding and polishing: During the grinding and polishing stage, pay attention to equipment selection and grinding amount control, and strive to achieve a uniform gloss on the marble mosaic surface.

5. Construction protection and finished product care

Protective measures during the construction process are essential to maintaining the quality of the final product. Strict protective measures should be taken at every stage from paving to polishing, such as closing the construction area and covering the finished product with soft carpets, to prevent accidental damage and contamination.

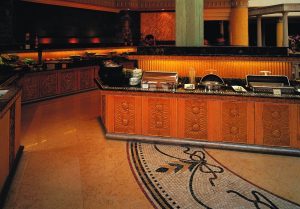

Hotel restaurant with marble mosaic

This article explores the improvement of marble mosaic construction methods, focusing on solving existing problems and anticipating future developments in construction technology. It presents innovative strategies and methods for paving technology, grouting reinforcement, flatness grinding, and polishing. The article emphasizes the importance of understanding the process and strict control of details in improving construction quality. It also stresses the need for protective measures during construction and finished product care to minimize damage to marble mosaics. The article calls on professionals in the industry to continue exploring and practicing new construction methods, sharing experiences and ideas to promote advancements in marble mosaic construction technology. The future of marble mosaic construction will focus on environmental protection, efficiency, and personalized design, presenting more beautiful architectural art.

People also ask

What is the construction process of marble mosaic?

Marble mosaics are a popular choice in modern architectural decoration due to their unique decorative effect and diverse color matching. They add an artistic atmosphere to interior spaces and provide a durable, easy-to-maintain surface. The construction process of marble mosaic floors involves paving, reinforcement, grinding, and polishing to ensure quality and the final decorative effect. The construction team must constantly adapt to new construction technologies to meet the increasing decoration standards in the building decoration industry. The careful selection of materials and careful construction process ensures the mosaic floor’s beauty and durability.