In the field of architectural decoration, granite is popular for its durability and beauty. Project cost control and material choice depend critically on selecting the correct granite specs and knowing its price range. Simultaneously, the granite paving process has to consider several important factors to guarantee the long-term durability of the material and final ornamental impact. This article will introduce the common specifications, price ranges and precautions of granite in detail.

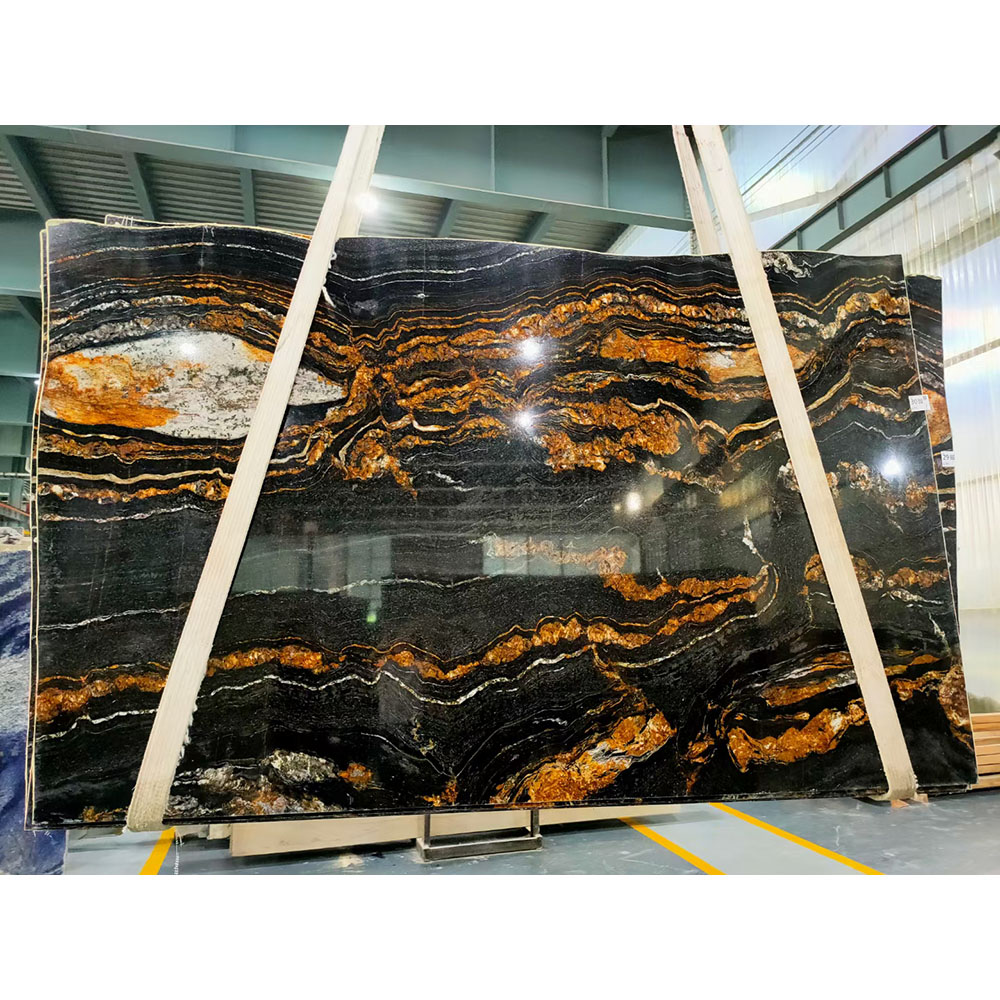

Magma Gold Prime Granite

Common specifications of granite

Rebound stone.

Generally, the size of the rebound street stone is about 100mm*100mm*100mm, and the top surface is square. Should the rebound street stone be laid on the pavement, the thickness can be cut to 50mm. The thickness, should it be utilised as a veneer, is 20mm or even less.

Mushroom stone

Mushroom stone usually measures 1000mm–1200mm long, 500mm–600mm wide, and 100mm–130mm thick.

Rough surface slab

Generally, the rough surface slab is 1000mm~1200mm long, 500mm~600mm wide, and 30mm thick. The typically used composite plate is 20mm thick, of which the surface material (marble, granite) is 3mm thick and the bottom plate (stone, tile, aluminium honeycomb plate) is 17mm thick. The thin plate is 10mm thick, generally 20mm thick, the curtain wall is 30mm thick, the mushroom stone paving is 30mm~50mm, the bridge deck decorative plate is 50mm thick or more.

Flat stone

Common stone measurements are 600*300, 400*200, 300*300. Granite is not advised if there are no particular paving design needs even if, in theory, it may be tailored or cut to any specifications on site and will raise expenses and labour waste. The thickness of the stone is 20mm–30mm (the thickness of the natural surface, litchi surface, and axe surface is not less than 30mm), and the thickness of the road is 50mm; 30mm thickness can also be used on roads with low traffic volume and no major vehicles.

Granite price range

Granite’s pricing mostly relies on numerous elements: quality and scarcity, thickness, plate standards and surface processing techniques. Domestic 20mm thick granite plates cost 50–200 yuan/ouxce. There are several techniques of stone processing, and the effects displayed are also various, including round edges, bevel edges, bottom reversed, etc. Ten to thirty yuan/㎡ is the processing cost. Imported products are slightly higher in price according to different categories and qualities.

(This pricing is typical mid-range product price. The paucity of natural resources, manufacturers, branding, customising and other factors will cause material prices to be erratic. I’ll not get into specifics here. The information above serves just for reference.)

Precautions for granite paving

Radiation

Stone is taken from the natural world; radioactive elements are typical and certain in it. In the “Limits of Radioactive Nuclides in Building Materials” (GB6566-2010) promulgated in China, the material standards are divided into three categories: A, B, and C according to the radioactivity level of decoration materials. Class A decorative materials’ manufacturing, sales, and usage are not limited either. Class B decorative materials can be used for Class II civil buildings, industrial building interior surfaces and all other outside surfaces of structures; they cannot be utilised for the inside surfaces of Class I civil buildings. Only for the outside surfaces of buildings and other outdoor uses are Class C decorative materials applicable.

Alkali

Alkali is a white crystalline substance that remains on the surface of the stone after evaporation, when water releases alkali, salt and other substances contained in the stone itself and the bonding materials along the pores and plate seams of the stone. In the design process, the alkali alkali phenomenon of stone should be considered in advance.

Scraps processing

The specifications of corner stones should be consistent with those of surrounding stones. The building’s corners ought to be cut with intention. Non-standard size edge stones can help to guarantee the effect in specific corners.

Granite is often composed of radioactive elements, thus it is important to check its radiation level before using it and subsequently verify its usage occasion.

On site paving

The key points of surface construction control mainly include material selection, sample making, layout and setting out, bonding layer control, seam width control, grouting skills, finished product protection, and layout control of important nodes.

Large outdoor waterwall stone carved black granite water stone fountains

One often utilised architectural component is granite. Key elements to guarantee the success of the project are its range of requirements, pricing range, and paving measures. By choosing specifications reasonably, controlling costs and paying attention to construction details, the decorative effect and durability of granite can be fully utilized. Knowing this knowledge would enable builders and designers to make better judgements and attain the ideal mix of usefulness and beauty.