In the field of architecture and decoration, granite is favored for its excellent physical properties and beautiful natural texture. The diversity of granite surface technology provides designers with a broad creative space, so that each piece of granite can show its charm in its own unique way. This article will introduce in detail the various surface technologies of granite, from rough natural surface to smooth polished surface, each technology has its specific application scenario and aesthetic value.

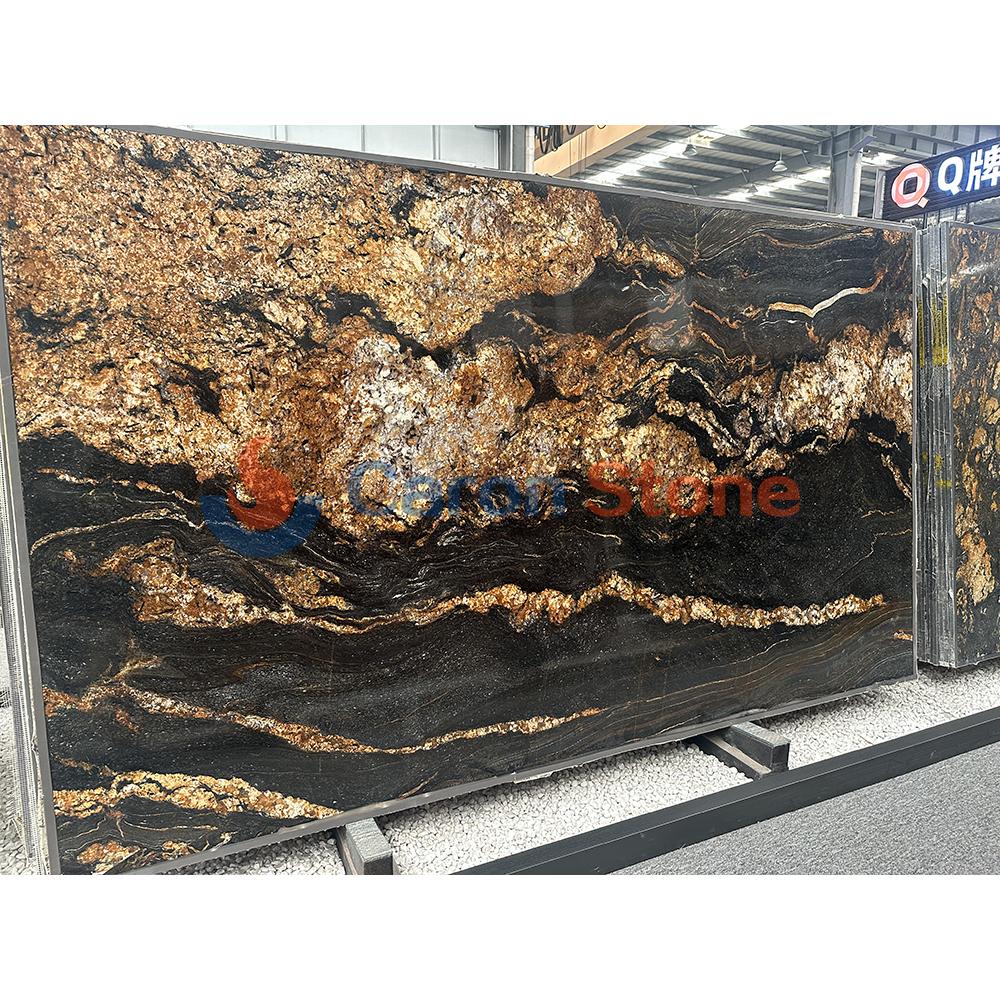

Good Brazil Black Cosmic Granite Slab Price For Interior Decoration

01 Machine cut surface

Directly cut and formed by equipment such as circular saws, sand saws or bridge cutters, the granite surface is rough and has obvious machine cut lines.

02 Matt surface

The matte surface refers to a flat surface with less polishing treatment on the surface using resin abrasives. Its brightness is lower than that of the polished surface, generally around 30-50, 60. It has a certain brightness, but the reflection of light is weak. Granite has a flat and smooth surface and a very low brightness plate.

03 Polished surface

Also called polished surface, it refers to a plate with a flat surface that is polished with resin abrasives to give it a mirror-like luster.

Generally, the brightness of stone can reach 80 or 90 degrees. Its characteristics are high brightness and strong reflection of light, which can fully display the rich and gorgeous colors and natural texture of granite itself.

04Fire-burned surface

Fire-burned surface refers to a rough surface made by processing the surface of stone with a high-temperature flame generated by acetylene, oxygen or propane, oxygen, or liquefied petroleum gas, oxygen as fuel.

Fire-burned surface has certain requirements for the thickness of granite to prevent the stone from breaking during processing. Generally, the thickness is required to be at least 2CM. The surface of the fire-burned surface is rough and natural, non-reflective, fast to process, and relatively cheap.

05Lychee surface

Lychee surface is a rough surface shaped like lychee skin formed on the surface of granite by hitting the surface of the stone with a hammer shaped like lychee skin. It is divided into machine lychee surface (machine) and hand lychee surface (handmade).

06Longan surface

Also called chopping axe surface, it refers to the rough surface shaped like the skin of a longan formed by staggered hitting on the surface of the granite with a straight hammer. Like the lychee surface, it is also divided into two types: machine and hand.

07Antique surface

In order to eliminate the thorny characteristics of the flamed surface, the granite is first flamed and then brushed with a steel brush 3-6 times to form an antique surface.

There are many ways to make an antique surface, such as water flushing, acid etching, direct steel brushing or high-pressure water flushing after flame. The processing of antique surface is time-consuming and the price is also relatively expensive.

08Pineapple surface

Pineapple surface is a plate shaped like pineapple skin by hitting the surface of granite with a chisel and a hammer.

Pineapple surface is rougher than lychee surface and longan surface. It can also be divided into coarse pineapple surface and fine pineapple surface.

09Mushroom surface

Mushroom surface refers to a plate shaped like an undulating mountain formed by hitting the surface of granite with a chisel and a hammer.

This processing method has certain requirements for the thickness of the stone. Generally, the bottom thickness is at least 3CM, and the raised part can be 2CM or more according to actual requirements.

10Natural surface

Natural surface refers to a processing method that uses a hammer to split a piece of granite from the middle to form an uneven surface like the natural surface.

11grooved

Open a groove of a certain depth and width on the surface of the granite.

12sandblasted

Use ordinary river sand or diamond sand instead of high-pressure water to wash the surface of the granite stone to form a decorative surface with a smooth frosted effect.

13water-jet

Use high-pressure water to directly impact the surface of the granite stone, peel off the softer components, and form a unique rough surface decorative effect.

14pickling

Use strong acid to corrode the surface of the granite stone, so that it has small corrosion marks, and the appearance is more rustic than the polished surface.

Large outdoor waterwall stone carved black granite water stone fountains

The diversity of granite surface technology not only enriches the visual effect of architectural decoration, but also meets different functional and aesthetic needs. Whether you are pursuing a natural and simple texture or prefer a smooth and bright mirror effect, granite can achieve the desired decorative effect through different processing techniques. With the continuous advancement of process technology, the application of granite will be more extensive, bringing more possibilities for modern architectural decoration.